About Digital Hydraulics

Digital Hydraulics - A precision hydraulic technology can be used by anyone Digital hydraulic technology is the latest international trend of development. It is an upgrade from servo hydraulic technology. The key of digital hydraulic control is precision servo closed-loop control technology, but the difference is the digital hydraulic uses the machinery closed-loop and feedback control, not the electronic. Because the digital hydraulic feedback is precision machinery, so hydraulic transmission control system is simplified. Users do not need to care about what is the PID, the frequency response, valve gain, and the characteristics of complex components, users only need to focus on the target needs. Digital hydraulic technology not only greatly reduces the threshold of pollution, interference and temperature range of the threshold is also greatly improved. Digital hydraulic allows everyone to use and can make good use of. |

As the core of intelligent hardware, Internet+ and Industrie 4.0 concepts, digital hydraulic system has emerged as the shared fundamental technology to drive equipment manufacturing industry to evolve towards IT application and intelligent optimization. As a matter of fact, an excellent automatic control system does not lie on its accurate algorithm. On contrary, no matter PID, Fuzzy logic, or advanced modern controlling technologies are adopted, the precise execution automatic control system. Digital hydraulic technology holds the key for automatic controlling systems to outperform the existing technologies to take a leapfrog development. When it comes to digital hydraulic system, it refers to that the state-of-the-art components (cylinder and motor) correspond to electrical impulse in term of their motion features. For instance, electric impulse frequency is consistent with the speed of the corresponding oil cylinder (angular velocity of oil motor), the number of electric pulse corresponds to the movement of oil cylinder (oil motor angle); and the precision of execution device will not be changed along with the varieties in loading, oil pressure and leakage. That’s why we name such a hydraulic technology as digital hydraulic system. Digital hydraulic system essentially aims to give the controlling right back to electricity and hydraulic power amplification. For this reason, it is the typical intelligent hardware and has been the common basic technologies for equipment manufacturing to realize "Industrie 4.0" technical revolution. | |

Digital Hydraulic Cylinder high precision and ultra low speed operation

L: Mr. ZHOU Ji, President of the Chinese Academy of Engineering M: Mr. YANG Shixiang, Inventor R: Mr. YANG Tao, AEMETEC Founder | ▊ YouKu |

Digital Hydraulic Actuator

| Digital Hydro-Motor

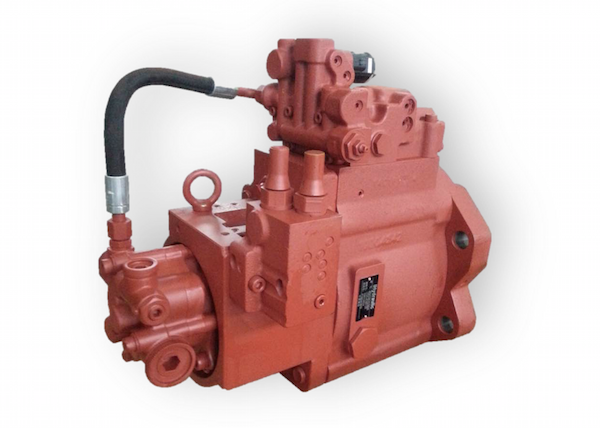

| Digital Programmable Sensitive Pump

|

The Digital Hydraulic Cylinder is a cylinder, digital servo valves, sensors, digital servo control to adjust the structure of the organic combination of high-tech integrated hydraulic drive and control a single device products. Particularly suitable for high-precision speed, position control, coordinated motion control drive system, especially in the large flow (one thousand liters / min), high-frequency servo control, digital hydraulic system has an unparalleled competitive advantage and cost-effective. | Digital Hydro-Motor includes a hydraulic motor, digital servo valves, sensors, digital servo adjustment control structure, it is a system composed of many components are integrated into a single device, high-tech hydraulic drive and control products. Particularly suitable for high-precision speed, torque control, coordinated motion control drive system, especially in the low speed high torque angle precision, high-frequency servo control, digital hydraulic system has an unparalleled competitive advantage and cost-effective. | Digital Programmable Sensitive Pump can be connected directly to a computer or network bus, precise control of the output of the hydraulic displacement, it is possible to precisely control its external work, both programmable output power can be achieved, can also be adapted to the sensitive load, constant power and other conditions need is Google launched a digital hydraulic products in new members, but also to achieve energy efficient operation of one of the finest hydraulic devices. |